Hi-tech Industrial Development Zone,Kexue Avenue, Zhengzhou, China.

Hi-tech Industrial Development Zone,Kexue Avenue, Zhengzhou, China.-

sales@sinofote.com

sales@sinofote.com

Hi-tech Industrial Development Zone,Kexue Avenue, Zhengzhou, China.

Hi-tech Industrial Development Zone,Kexue Avenue, Zhengzhou, China. sales@sinofote.com

sales@sinofote.com

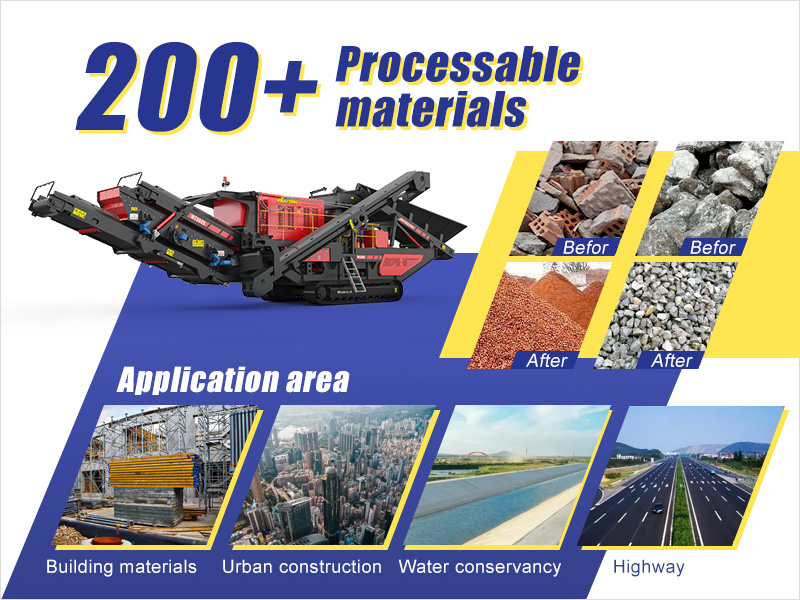

Mobile crushing and screening plant is a kind of mobile crushing equipment that integrates crushing and screening operations. It is widely used in processing granite, limestone, quartz, construction waste, concrete, gold ore, iron ore, coal and other rocks, ores and other minerals.With a variety of combinations, users can adopt different solutions according to different site conditions.

Portable stone crusher is suitable for crushing soft, hard and super hard materials, which is widely used in smelting, building materials, highway, railway, water conservancy, chemical industry and many other departments. It is also the important equipment of mining machinery. Fote portable stone crusher is a kind of new, high efficiency and energy saving mobile crusher, which has been exported to Russia, Kazakhstan, Mongolia, Azerbaijan, North Korea, Vietnam, Malaysia, Turkey, Iran, Canada as well as other countries and regions.

Application fields: mining, stone mining, highway (railway) construction, urban construction waste treatment, etc.

Applied materials: --- concrete scrap, iron ore, copper ore, gold ore, manganese ore, gravel, granite, river stone, basalt, limestone, dolomite, quartz and coal.

1.Unit integration and flexible movement.There is no need to lay foundations, and the work can be carried out directly after entering the site, with minimal requirements for the work site and reduced raw material transport costs.

2.The mobile crushing plant has a compact structure, small turning radius, and is convenient for conversion, entering and exiting the site.

3.Reduce manpower requirements and increase overall productivity

4.It can be equipped with a generator set to meet the requirements of normal operation in complex situations such as no electricity and power failure.

Material: Solid construction wastes

Capacity: 150-200t/h

Output Size: 0-10-20-30mm

Product Configuration: mobile jaw crusher, vibrating screen, vibrating feeder

The project is fully designed by FTM and we recommend the most advanced mobile crushing plant. Compared with the fixed production line, the mobile crushing plant project has the advantages of shorter cycle time and faster subsequent turnaround, and also reduces the investment risk for investors. In addition, the excellent depreciation and value retention capability can help customers to quickly start new projects or sell directly for cash

According to the different production process, portable stone crusher can be divided into tracked portable stone crusher and wheeled portable stone crusher and construction waste crushing plant.

Tracked mobile crusher can be divided into four series-tracked cone crusher, tracked portable jaw crusher, tracked portable impact crusher, tracked portable mobile crushing and screening plant. Recommended for use in challenging worksite environments when needed.The machine uses a hydraulic system to drive the crawler, so as to achieve smooth running, and can adapt to a variety of complex job site conditions. It is widely used in mineral mining, stone mining highways (railways) and bridges, urban construction waste disposal and many other fields.

Recommended for use in environments with moderate transfer distances when permitted by the work environment. Customized design can be made according to different crushing industries, “first crushed and then sieved” or “first sieved and then crushed”, crushing and screening can also be carried out separately.

Construction waste crushing plant produced by Fote Machinery has adopted advanced construction waste disposal technology, which can process industrial waste slag, cinder, coal rock, slag, fly ash, building materials, non-metallic solid waste and other solid waste into new building materials which are conforming to specification testing quality. With the different configurations, the construction waste rate can reach 80-100% without secondary pollution. It can achieve ideal environmental protection effect of near zero pollution and zero emissions. Customers can also choose fixed type construction waste crushing line according to the construction requirements.The construction waste can be used as fine concrete aggregate after being crushed by mobile crusher. It can also be used to produce block bricks, tiles and highway roadbed, which has wide application ranges.

Portable rock crusher can be equipped with different crushing and screening equipment according to the actual situations, such as vibrating feeder, jaw crusher, cone crusher, impact crusher, belt conveyor, the main control device, power device, etc. Portable stone crusher can be also equipped with the double-deck vibrating screen, four-deck vibrating screen, etc.

As the professional mobile crusher manufacturer, Fote Machinery has portable stone crusher for sale, which includes wheeled portable stone crusher and crawler portable stone crusher, of which wheeled portable stone crusher price is low, crawler portable stone crusher has advanced technology. With cone crusher, jaw crusher, impact crusher and vibrating screen, they can form joint or closed loop type. If you are interested in our equipment, please leave us a message or send inquiries to us, and our professional sales staff will contact you as soon as possible!

MOBLIE IMPACT CRUSHER TECHICAL PARAMETERS

| Model | FTM938F1210 | FTM938FW1214 | FTM1149F1315 | FTM1349HD1110 | FTM1349HD1315 |

| Transportation Length(mm) | 12000 | 12000 | 13900 | 15450 | 15450 |

| Transportation Width(mm) | 2550 | 2550 | 2900 | 2950 | 2950 |

| Transportation Height(mm) | 3900 | 3900 | 4450 | 4500 | 4500 |

| Maximum Length(mm) | 12500 | 12500 | 13900 | 15450 | 15450 |

| Maximum Width(mm) | 3250 | 3260 | 3250 | 3250 | 3250 |

| Maximum Height(mm) | 5100 | 5200 | 5200 | 5200 | 5200 |

| Weight(t) | 39 | 44 | 54 | 62 | 62 |

| Crusher Model | PF-1210 | PF-1214 | PF-1315 | HD1110 | HD1315 |

| The Maximum Feeding Size(mm) | 350 | 350 | 500 | 400 | 700 |

| Production Capacity(t/h) | 70-130 | 100-180 | 130-250 | 112 | 280 |

| Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 | ZSW130×4900 | ZSW130×4900 |

| Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M | B800×11M | B1200×11M |

| Side-opening Belt conveyor(Optional) | B500×3.2M | B500×3.2M | B650×4M | B650×4M | B650×4M |

| Genset(Optional) (kw) | 320 | 320 | 400 | 320 | 440 |

| Iron Separator (Optional)(kw) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-8 | RCYD(C)-12 |

MOBLIE JAW CRUSHER TECHNICAL PARAMETERS

| Model | FTM938HD80 | FTM1149HD98 | FTM1349HD110 | FTM1349HD125 |

| Transportation Length(mm) | 12600 | 13500 | 14500 | 15200 |

| Transportation Width(mm) | 2600 | 2700 | 2800 | 2900 |

| Transportation Height(mm) | 3870 | 4200 | 4450 | 4500 |

| Maximum Length(mm) | 12500 | 14000 | 16100 | 16700 |

| Maximum Width(mm) | 4100 | 4500 | 5100 | 5100 |

| Maximum Height(mm) | 4100 | 4900 | 5000 | 5300 |

| Weight(t) | 39 | 57 | 55 | 65 |

| Tire Configuration | Dual-axial | Dual-axial | Dual-axial | Dual-axial |

| Jaw Crusher | HD80 | HD98 | HD110 | HD125 |

| Maximum Feeding Size(mm) | 500 | 550 | 660 | 800 |

| Discharge Opening Size(mm) | 50-150 | 75-175 | 100-200 | 125-225 |

| Capacity(t/h) | 85-275 | 110-350 | 215-510 | 280-650 |

| Vibrating Model | ZSW380×95 | ZSW420×110 | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B800×8.5M | B1000×9.5M | B1000×11M | B1200×11M |

| Side-opening Belt conveyor(Optional) | B500×3M | B650×3.5M | B650×4M | B650×4M |

| Genset(Optional) (kw) | 200 | 250 | 270 | 400 |

| Iron Separator (Optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 | RCYD(C)-12 |

Copyright© 2025 Henan Fote Heavy Machinery Co., Ltd. All Rights Reserved. Privacy Policy